The Green Room: Appletree Surfboards

We caught up with the team at Appletree Surfboards to find out what they’re doing to address sustainability issues.

When you purchase gear through links on our site, we may earn a small commission. Here’s why you can trust our tests and our affiliate partner.

We caught up with the team at Appletree Surfboards to find out what they’re doing to address sustainability issues.

Welcome to the Green Room

Appletree! Let’s talk about your philosophy to sustainability.

Appletree’s commitment to manufacturing long-lasting boards is probably quite well known by now. That philosophy has been there since Appletree was founded. The company started with a vision of brothers Wieger and Jorrit, passionate surfers and kiters, who felt that their surf and kiteboards should not only perform well, but also last longer. Their first experiments took place in 2006 in a shed and an old caravan, on the apple orchard where they were born and raised. Around this time kiting was growing in popularity, but traditional surfboards couldn’t withstand the sport’s demands. Board after board buckled or snapped. This led the brothers to develop a new manufacturing technique in 2014, resulting in Appletree’s boards being a lot more durable than your traditional production board. Therein lies the heart of Appletree’s sustainability vision: the longer lifespan of the boards means less impact on the environment. Being a family business, we aren’t pressured by large investors to continually increase sales, allowing us to keep that vision at the heart of things.

But for you it’s not enough just to make long-lasting boards, right?

Yes, what may be less well known is that the Appletree team is working on much more than that. From the beginning, we set ourselves sustainability goals. Although we have already achieved many goals and made progress on many fronts, in retrospect we can also argue that the goals we have set so far were too vague and not easily measurable. We were doing things mostly on gut feeling and because we felt it was the right thing to do. But we could not always back up actions with data on whether we were actually taking the right steps to achieve the goals we had set for ourselves. Plus many of the goals we never really communicated with people outside Appletree, so no one could really hold us accountable up to now except ourselves.

There is nothing wrong with following your gut feeling!

No, especially when driven by passion and common sense. But achieving sustainable change in your value chain requires professionalization. Where Appletree might have always been a company doing sustainable things, we are now working much more strategically towards actually being a sustainable company. We are currently establishing a baseline measurement to target our actions and support them with future data. Although not mandated for a company of our size, Appletree has decided to gradually align with the Corporate Sustainability Reporting Directive (CSRD) and European Sustainability Reporting Standards (ESRS). These are part of broader European regulations aimed at accelerating a green and just transition. While many companies see CSRD and ESRS as complex and challenging, we have come to view them as valuable frameworks that help us work towards a more sustainable value chain in a transparent, organized, innovative and reasoned way.

Tell us more about these CSRD and ESRS requirements.

Sustainability means more to us than just the environment, it always has. What the CSRD/ESRS kind of requires you to do is to reflect and, if material, report on Environmental, Social and Governance topics. We are currently focused on thorough data gap assessments, re-mapping our value chain, and identifying material aspects of our business. This integral part of our business strategy demands substantial time to organize and maintain, ensuring we address core issues rather than just low-hanging fruit. Any claims of non-materiality must be substantiated. We understand this might still seem quite abstract. Let us give an example: you can’t claim that using fair-trade toilet paper in your company is important to report on, while ignoring the structural underpayment of your own employees as something important to address or report. Obviously, a report does not solve world issues. But surely we can assume that after reporting that your company is performing poorly on something, your company does not decide to keep doing it poorly. Right? It forces you to be innovative and that is exactly where our strengths lie.

So what does this all mean in practice?

It’s not in our nature to take actions only on paper; we are, above all, doers. What we do and what our plans are for the future and what it means to those riding Appletree boards is what matters. Let’s begin with the heart of the company: the Appletree factory and the team. The shed on the Apple Orchard has since been upgraded to a 3500 square meter factory in Portugal, and the team of two brothers has expanded to a close-knit team of 35 people. This also means Appletree is responsible for supporting 35 families. We prioritize good working conditions, fair treatment and a motivating workplace. Thankfully we are already pretty far down that road. Now, the next step is to report on that. Unlike vague claims, from next year on we will report transparently on wage gaps, the goals we set to improve working conditions and much more. This isn’t about self-promotion. This is about transparency and being held accountable for something.

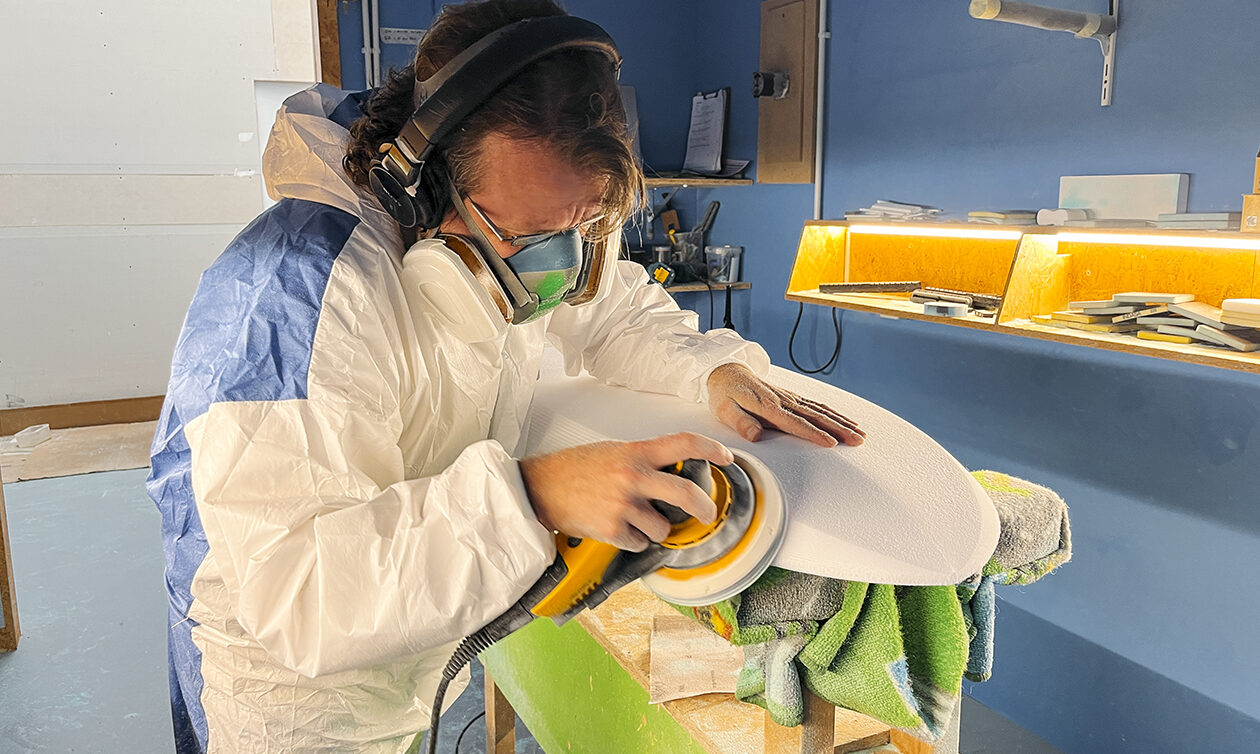

The charm of messing around in a shed might have faded a bit, because the safety of our employees comes first. Although there is still plenty of playing around, we can assure you that now it is with proper precautions only. We are pretty strict about keeping the factory clean, wearing protective gear, handling the raw materials safely and so on. Our responsibility extends to our suppliers’ employees, which is why we work almost exclusively with European suppliers to ensure compliance with European standards and legislation. We are gradually mapping out our suppliers’ practices in Environment, Social, and Governance (ESG) and discussing/setting our own minimum requirements for suppliers.

Let’s get back to the boards themselves. How does your philosophy extend to product design?

Our product design is rooted in Ecodesign principles, a key aspect of the circular economy. One principle is to consider at the design stage whether the product or material is truly necessary. This can even involve developing/exploring other business models, like Product-As-A-Service (PAAS). But currently, we focus on ensuring each product provides a real improvement, solves an issue, or is a well-reasoned addition. This is one of the reasons why we avoid producing seasonal products, which often offer minimal changes and encourage unnecessary consumption.

Another crucial Ecodesign principle is product durability and repairability. This is what we’ve been focusing hard on since the founding of Appletree. Our unique manufacturing technique makes our boards a lot more durable than the average production boards. Our waterproof foam prevents the need for immediate repairs since it does not absorb water. However, we do recommend repairs, which are straightforward with our instructional repair videos, further extending the boards’ lifespan.

And what about the actual production process?

We’re proud to be Ecoboard certified by Sustainable Surf, supporting the board-riding community in creating, buying and riding high-performance sustainable boards. While this doesn’t mean our boards are eco-friendly, we’ve implemented several production practices to reduce our environmental impact. Besides ensuring that our unique manufacturing technique makes the boards last much longer, it has another big advantage. Our vacuum infusion technique optimizes the resin-to-fiber ratio, allowing us to use fewer materials while producing stronger boards. Additionally, we use 40% bio-based resin in all our boards.

The Ecodesign principles include the use of reused or recycled materials. We’re especially proud of our agreement with our foam supplier, as we know many shapers struggle with this. We return all our leftover foam, including CNC machine cut-offs and shaping bay dust, which they recycle into new foam without quality loss. To facilitate this, we invested in a compactor that compresses foam waste into manageable packages, aligning with our goal of closing as many production loops as possible.

What other steps have you implemented in the factory?

Just as we ensure the longevity of our boards, we prioritize durable and repairable factory machinery. We invest in high-quality equipment that we can often repair ourselves. When necessary, we partner with specialized companies. Employee safety and health are paramount; that is why we work with experts who adhere to strict environmental and health standards.

Efficient use of energy and resources is also vital to us. We minimize energy consumption with energy-efficient machines and source about 95% of our materials from Europe. Our factory has always had a green energy contract, but our goal was to run entirely on renewable energy. As of December 2023, we’ve achieved this by installing solar panels on our factory roof. The sunny climate in Portugal generates more energy than we need, allowing us to charge our electric vehicles with the surplus.

It seems you truly have a sustainable mindset and are not just ticking boxes.

Yes we feel this is embedded in the entire Appletree team. Our culture fosters accountability for missteps, and motivation for improvement and innovation. There are so many great examples of this – waste that is separated with great precision so that it can be recycled properly, our office manager who gets a brilliant idea at home to reuse our packaging material and give it a new function, the quality team making new templates for pads from the cut-offs of other pads so that EVA waste is limited, our hotcoat team supporting charities through unique board art, and the list goes on!

Although we are happy with everything we have achieved so far, we are definitely not there yet! Our focus for the coming year(s) is to get ready for reporting in line with the ESRS. The aim isn’t just the reporting itself, but to reflect on the areas we previously mentioned and derive meaningful conclusions and actions from that process. But we have many more plans. On top of our list is performing Life Cycle Assessments (LCA) for our glass and carbon boards to pinpoint where we can achieve the most significant sustainability improvements. This will help us better direct our resources and efforts. We also aim to gain a clearer understanding of the boards’ end-of-life phase.

How can fans of Appletree boards find out more about this?

As soon as we have more data at our disposal, we will add it to the digital passports of our boards. Every Appletree board already comes with a digital passport featuring an NFC tag, but it currently holds limited data. By sharing our LCA data, we aim to offer more transparency for those already riding an Appletree board or thinking about buying one.

Any last words about future plans?

We are actively exploring more sustainable materials with several partners and will continue doing this. However, we want to ensure that any new materials do not compromise the durability of our boards. Extensive research will be necessary to determine if these materials are viable before we implement them.

You can get the latest goodness from the world of kiteboarding by subscribing to our print edition. You'll get 5 packed issues, plus a free tee and free digital access. And you'll be directly helping with our sustainability efforts too!

Check it out now