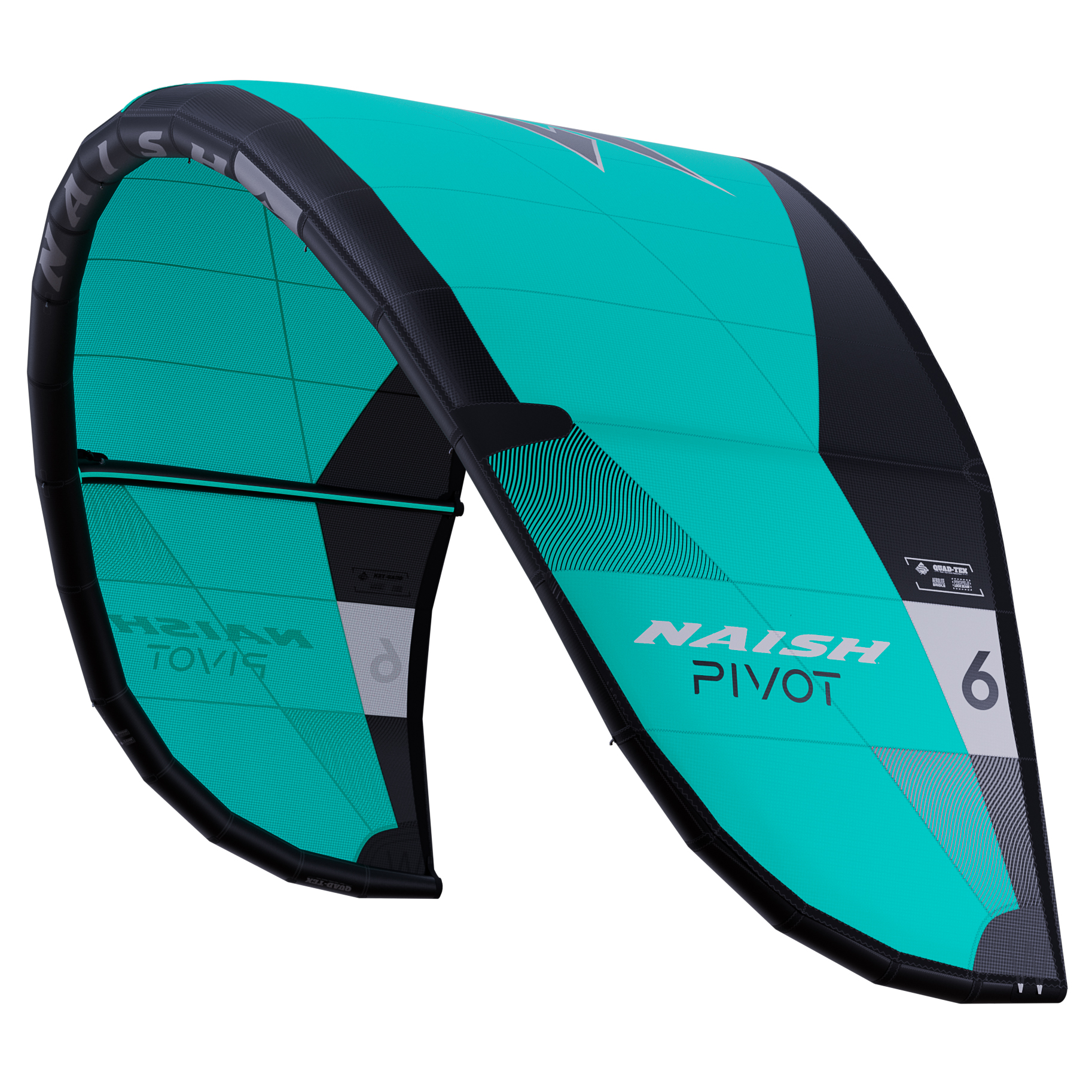

A major change with the latest Pivot is the Profile Lock Seam and Load Seam. What does this mean for the kite’s durability and performance?

This year we focused a lot on new construction features. The Profile Lock Seam is a seam that runs along the deep point in the profile of the kite, where there is a lot of load on the canopy. This keeps the profile locked and tight over time, meaning that over your sessions your kite still feels brand new, and eliminates the feeling of ‘bagging out’.

The new Diagonal Load Seam is an extra load seam to the head of the side struts on the Pivot. In previous seasons we had this seam only run to the center strut of the kite, but now having an extra one helps distribute the steering input (as the seam runs from the steering line attachment) throughout the kite, and also keeps the canopy tighter over time.

You’ve also updated the bridle system and lines. Tell us what you’ve done here and why.

New to this year we have TLS 400 bridle lines on the Pivot. These lines are super thin and minimize drag through the air. Another benefit people also don’t talk about as much is the aid in water relaunch. The thinner lines break through the surface tension of the water easier, so that last bit of the kite relaunch, which can be tricky in light winds, becomes far easier to break through. We also used a new construction for the bridle point attachments which is cleaner and stronger than before, giving the kite added durability and higher-end finish. Lastly we worked on perfecting the bridles across the range and ensuring that perfect tension was achieved across the kite.

Are there any other changes you’d like to point out to our readers?

We have added the bladder cap construction to the Pivot, which was designed to withstand the higher stresses on the bladder in the Nvision kites. This is a clean, rounded wingtip and strut-end closure system which evenly distributes the pressure of the bladder, eliminating any places for the bladder to blow out from, and allows higher pressures in inflation. The ends are also very easy to access allowing for repairs (rarely needed!) to be done with ease. A few of the sizes have also had some changes to their profile. Last year we went quite efficient and shallow in certain sizes/areas, but this year we have achieved the same forward drive, with a deeper more powerful profile through bridling and profile curve changes.

Who was involved with the redesign and testing of the new Pivot?

It is always a team effort to bring a new kite to the market. I am the lead on the product, but work very closely with Des Walsh, his son Tim, the whole team at Naish, our importers, team riders and retailers. Des is an endless wealth of knowledge and his kite testing is second to none. It is so important to have someone to bounce thoughts off and give a different point of view, as sometimes you find yourself down a rabbit hole and you need someone to bring you out with another viewpoint. Talking to people and getting everyday riders to test this stuff is also so important. Another group that play a great role is our team at the factory at IKP. They work tirelessly with us to try new things, help innovate and ensure we have the highest quality product available.

Now that the latest Pivot is out, can you give us any hints as to what you are working on next?

I am currently busy working on the next Boxer, and something that people are very excited about, which is the Q-Series Psycho. Other than those two, there are always many projects on the go, from testing materials, new shapes or learning things to further our knowledge as a team. We have a great thing going on at the moment at Naish, and I’m sure you will be pleasantly surprised over the coming years as to what the team will produce, not just in kiting, but across the board.